| Name | Vinyl flooring (LVT flooring,click LVT flooring) |

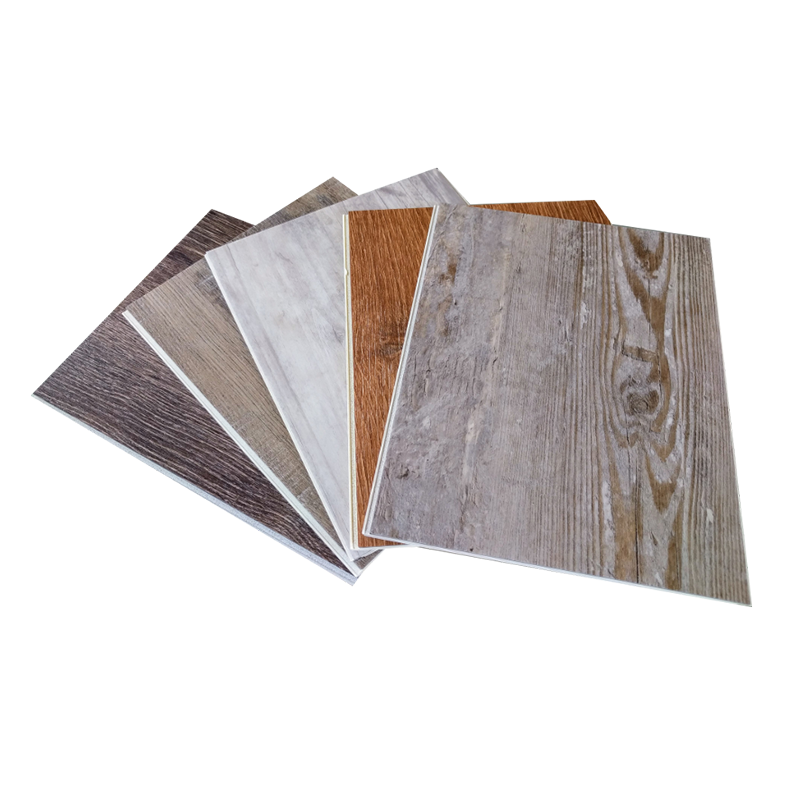

| Color | Based on 3C lap dip series number or as your samples |

| Board Thickness | 2.0mm/2.5mm/3.0mm or customized |

| Wearing Layer Thickness | 0.2/0.3/0.5/0.55/0.7 mm or customized |

| Surface Texture | Deep Grain,Wood Grain,Marble Grain,Stone,Carpet |

| Surface Treatment | UV-Coating |

| Installation | Click system,Loose lay,Dray Back/Glue Down |

| Delivery Time | 15-25 days |

| Size | Inch or MM |

| 914.4*152.4mm*2.0mm, 36pcs/ctn,120ctns/pallet,10pallets/20GP | |

| 914.4*152.4mm*2.5mm, 30pcs/ctn,120ctn/pallets,10pallets/20GP | |

| 914.4*152.4mm*3.0mm, 24pcs/ctn,120ctns/pallets,10pallets/20GP | |

| 457.2*457.2mm*2.0mm,30pcs/ctn,100ctns/pallet,10pallets/20GP | |

| 457.2*457.2mm*2.5mm,24pcs/ctn,100ctns/pallet,10pallets/20GP | |

| 457.2*457.2mm*3.0mm,20pcs/ctn,100ctns/pallet,10pallets/20GP | |

| Project Solution Capability: | graphic design, total solution for projects, Cross Categories |

| Place of Origin | Shandong China |

| Product Type | Vinyl Flooring |

| Usages | Indoor |

| Features | Waterproof,Wear resistant,Anti-slip,Moisture Proof,Fireproof,durable, anti-scratch, anti-bacterial. |

| Market | Export to American,Canadian,European Market,Part Asia,Africa Countries.Australia Market |

| Warranty | 10 years for commercial and 25 years for residential |

| Material | PVC, Recycle |

| Certificate | CE, ASTM, Floor score, Green Guard, GB, ISO9001 |

1.How do you guarantee the quality of your PVC vinyl flooring? Each step is strictly controlled by the QC team to make sure all our products turn out great. Our products have a limited warranty as long as 7~15 years. 2.How about the delivery time ? Lead time since receipt of 30% T/T deposit payment : 30 days . (Samples will be prepared within 5 days.) 3.Do you offer other products besides PVC vinyl flooring? Yes. Besides PVC vinyl flooring we also provide as T-molding, skirting , Click system vinyl flooring, WPC vinyl flooring AND so on interior decoration material. 4.Do you charge for the samples ? According to our company policy ,We provide free samples ,But the freight charges need customers pay. 5.Can you produce according to customers' design ? Sure,We are professional manufacturer ,OEM AND ODM are both welcome .

1.How do you guarantee the quality of your PVC vinyl flooring? Each step is strictly controlled by the QC team to make sure all our products turn out great. Our products have a limited warranty as long as 7~15 years. 2.How about the delivery time ? Lead time since receipt of 30% T/T deposit payment : 30 days . (Samples will be prepared within 5 days.) 3.Do you offer other products besides PVC vinyl flooring? Yes. Besides PVC vinyl flooring we also provide as T-molding, skirting , Click system vinyl flooring, WPC vinyl flooring AND so on interior decoration material. 4.Do you charge for the samples ? According to our company policy ,We provide free samples ,But the freight charges need customers pay. 5.Can you produce according to customers' design ? Sure,We are professional manufacturer ,OEM AND ODM are both welcome .

Supply Ability:10000 Square Meter/Square Meters per Day Lead time:

Supply Ability:10000 Square Meter/Square Meters per Day Lead time: | Quantity (square meters) | 1 - 1000 | 1001 - 2000 | 2001 - 5000 | > 5000 |

| Lead time (days) | 10 | 20 | 30 | To be negotiated |

There are multiple luxury vinyl flooring constructions that have been engineered to answer the different needs in both commercial and residential spaces. Innovations in the LVT product category have made the installation process easier for home-owners and installers. 1.Glue Down: Also known as “dryback,” glue down is the most commonly used in commercial applications because of the heavy foot-traffic environments and heavy rolling loads. This installation method requires the use of an adhesive when installing. There have been many innovations with adhesives in the past 10 years beyond the traditional troweled-on application, including roll-on, peel, and stick, and spray adhesives. 2.Click: Unlike glue down, click does not require the use of adhesives, as the planks or tiles are installed by using the tongue and groove locking system on the edges of the product. This provides for a quicker and easier installation versus glue down/dry back. However, traditional click LVT has issues with sub-floor irregularities and dimensional stability, so it has mostly been replaced by the improved rigid-core click product category. 3.Rigid Core Click: This LVT has an installation process similar to the click LVT, but typically has a thicker and more rigid construction. The rigid core LVT construction provides better resistance to indentations, better dimensional stability, and added comfort-under-foot. There are 2 general rigid core categories: WPC (wood plastic core) and SPC (solid polymer core or stone plastic composite). WPC was the original rigid core construction introduced in the US market but experienced issues with product construction and dimensional stability. SPC flooring was introduced to fix the flaws that WPC flooring experienced, offering a more structurally stable and waterproof construction. 4.Loose Lay: This LVT version is a thicker product construction versus glue down (typically 5.0mm). Most manufacturers promote loose lay LVT in smaller spaces with no rolling loads since minimal adhesive is required around the perimeter. The manufacturers recommend an adhesive be applied to loose lay LVT in a medium-sized room (width of the room larger than 20 feet) on the perimeter of the room, or even a grid of adhesive every 8 feet. In applications with heavy foot traffic or rolling loads, manufacturers recommend doing a full spread of adhesive with loose lay which turns it into a glue-down installation. The benefits of loose lay are a quicker installation process, acoustical benefits, use on sub-floors with high moisture content, installation over existing floors, and more comfort-under-foot.

There are multiple luxury vinyl flooring constructions that have been engineered to answer the different needs in both commercial and residential spaces. Innovations in the LVT product category have made the installation process easier for home-owners and installers. 1.Glue Down: Also known as “dryback,” glue down is the most commonly used in commercial applications because of the heavy foot-traffic environments and heavy rolling loads. This installation method requires the use of an adhesive when installing. There have been many innovations with adhesives in the past 10 years beyond the traditional troweled-on application, including roll-on, peel, and stick, and spray adhesives. 2.Click: Unlike glue down, click does not require the use of adhesives, as the planks or tiles are installed by using the tongue and groove locking system on the edges of the product. This provides for a quicker and easier installation versus glue down/dry back. However, traditional click LVT has issues with sub-floor irregularities and dimensional stability, so it has mostly been replaced by the improved rigid-core click product category. 3.Rigid Core Click: This LVT has an installation process similar to the click LVT, but typically has a thicker and more rigid construction. The rigid core LVT construction provides better resistance to indentations, better dimensional stability, and added comfort-under-foot. There are 2 general rigid core categories: WPC (wood plastic core) and SPC (solid polymer core or stone plastic composite). WPC was the original rigid core construction introduced in the US market but experienced issues with product construction and dimensional stability. SPC flooring was introduced to fix the flaws that WPC flooring experienced, offering a more structurally stable and waterproof construction. 4.Loose Lay: This LVT version is a thicker product construction versus glue down (typically 5.0mm). Most manufacturers promote loose lay LVT in smaller spaces with no rolling loads since minimal adhesive is required around the perimeter. The manufacturers recommend an adhesive be applied to loose lay LVT in a medium-sized room (width of the room larger than 20 feet) on the perimeter of the room, or even a grid of adhesive every 8 feet. In applications with heavy foot traffic or rolling loads, manufacturers recommend doing a full spread of adhesive with loose lay which turns it into a glue-down installation. The benefits of loose lay are a quicker installation process, acoustical benefits, use on sub-floors with high moisture content, installation over existing floors, and more comfort-under-foot.